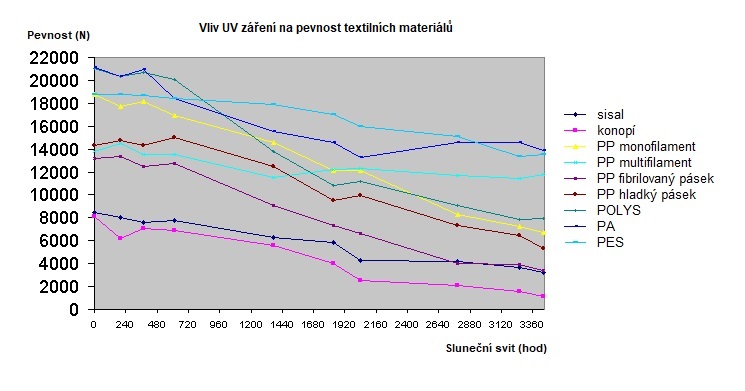

UV radiation, as a natural part of solar radiation, affects almost all textile materials used in the production of technical textiles. UV radiation causes degradation of the material and thus the basic building elements - fibres or strips - lose their strength.

The intensity of UV radiation is variable and is proportional to the intensity of solar radiation in different geographical areas. We measure UV intensity in kLy (kilolengleys), units that express how much UV energy falls on one mm3 per year. A generalized map of areas by UV intensity.

UV radiation has the greatest effect on polypropylene. This material, which is the basis of many industries, needs to be protected from the effects of UV radiation. This is done with the help of special additives - stabilizers. The stabilization of polypropylene against the effects of UV radiation is governed by the intensity of this radiation in individual areas.

If, for example, we have a polypropylene rope stabilized at 100 kLy, i.e. for the conditions in Central Europe, this means that this rope must not lose more than 50% of its strength within one year. In order to avoid relatively large strength losses (especially for safety applications), it is necessary to select a stabilization that is higher than the UV intensity in the given area.

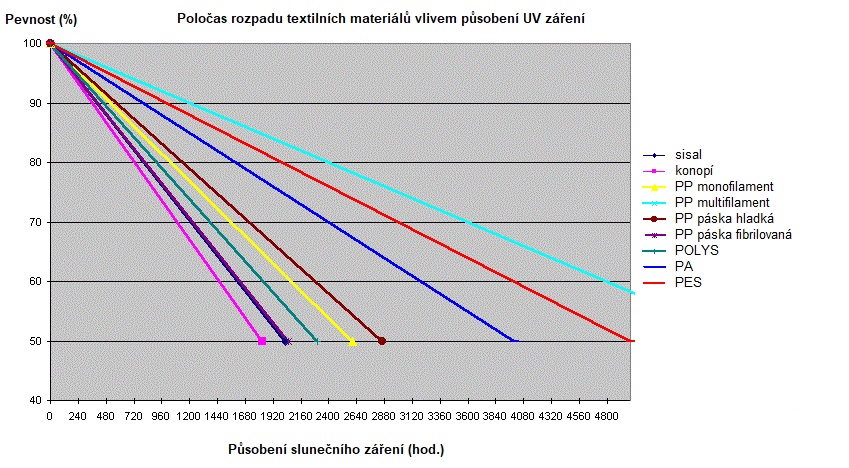

It is generally known that UV radiation has the least effect on polyester. However, by long-term measurements and testing our products - ropes made of various materials - we came to some interesting results: the smallest strength losses were found in ropes made of the polypropylene multifilament fibre MULTITEX, which was stabilized to 80 - 100 kLy as standard, see the effect of UV radiation on the strength of textile materials and the half-life.

Whenever ropes are exposed to UV radiation for a long time, we try to use ropes made of MULTITEX fibre - work and safety nets, electric fence ropes, ropes on playgrounds, etc.