The new extrusion line, which has replaced two original lines and will shortly replace a third, was bought last summer by Lanex for its plant in Bolatice. Seven trucks from the Italian manufacturer brought it in August.

"Our employees first set it up according to the plan, then came the experts from Italy, who began to assemble it first mechanically, then they installed the wiring, assembled the electronic circuits and wired up the other media. It was quite demanding work, which lasted until the first week of September," said Lanex CEO Martin Václavek.

D Day came on Wednesday, 11 September, when the new line came to life. "First we gave it a dry run, then we used the minimum amount of raw materials, so as not to waste them unnecessarily. Currently, polypropylene tape production is running at full capacity, the production of special polysteel fibre is still being fine-tuned to achieve the declared parameters," added the CEO.

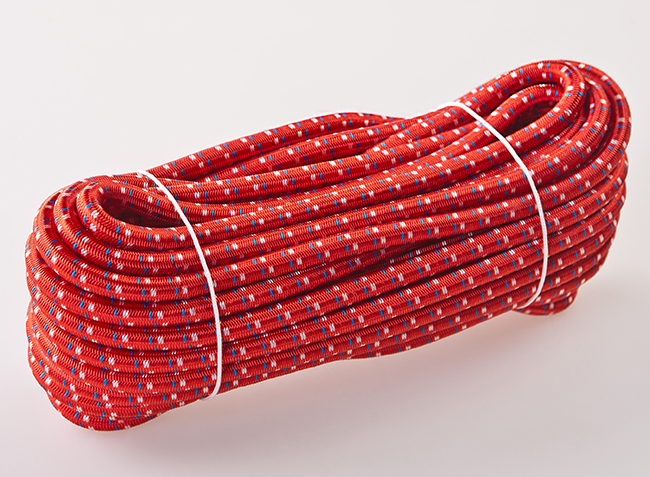

The line basically handles the entire production of fibre, right from the input raw material, which is granulate and is a by-product of diesel production. Stabilizers and dye are added to it at the input. The new equipment can produce both polypropylene tape and polysteel monofilament fibre, which is a unique combination of polyethylene and polypropylene. It will replace with two older generation machines. The monofilaments are immediately spun onto a spool on down-the-line machines to form twine, which is already the basic strand for making ship rope. The new extrusion line cost 1.6 million Euros, of this amount, 30 percent of the cost was covered by a European Union subsidy aimed at energy saving. While the capacity of the line will increase by 50 percent compared to the original two machines, the energy consumption will drop to 40 percent of the original consumption.

Of course, the workers on both the original lines will continue to have skilled work at Lanex. Either they operate the new equipment or two other extrusion lines, one of which has been at Lanex for several decades, the other, barely four years old, was bought by Lanex last year and came over from Conrop's Vítkov plant. All three extruders, and the regranulation line too, have been newly located in one production hall. This enables worker safety to be optimized , as workers can operate multiple machines at the same time, or assist each other. In the future, Lanex plans to retrofit the new line with even more components, which would allow it to replace the third, oldest extruder. The sophisticated equipment will significantly increase Lanex's competitiveness on world markets, as very few companies in Europe currently have such machinery at their disposal

The photo shows the engineer Jiří Theuer operating the new line.