Testing static ropes according to EN 892

Average

This quantity is measured on the rope at a load of 10 kg for single ropes, 6 kg for half ropes and 5 kg for double ropes. It is therefore very difficult to check the diameter of the rope accurately in home conditions.

Weight

Gives the weight of the rope per metre length. Single ropes without further modification weigh 52 to 88 grams, half ropes about 50 grams and double ropes about 42 grams per metre. The core of the rope must be at least 50 % of its total weight.

Number of standardized falls

The number of falls that the tested rope must catch under conditions given by EN 892. This standard requires a minimum of 5 falls for single ropes with 80 kilogram weights. Half ropes are tested with a weight of 55 kg. In double ropes with an 80 kg weight, two ropes are always loaded and the minimum number of falls is 12. The number of captured falls in tests is a direct measure of the rope’s safety (strength) margin. In practice, no new rope - if it is in good condition and handled properly - can break under impact loads. The rope’s safety is gradually reduced as the material ages and wears, i.e. by influences that reduce its strength. Moisture, which often affects the fibres of the polyamide from which the rope is made, also reduces its strength.

Maximum impact force

The impact force is the force that is generated during the first fall under defined conditions (mass of the weight, fall factor...) and is absorbed by the rope. In testing, the impact force in the rope increases with each additional fall completed, and the rate at which it increases is dependent on the resulting number of standard falls it undergoes. The higher the number of standard falls, the longer the rope life is for the user. Practical use of ropes in the field or on training walls differs from laboratory conditions. In a standard fall test, the end of the rope is fixed, but in practice belay devices and systems have some slippage of the rope, which means that the fall is caught dynamically. The dynamic restraint then distributes part of the fall energy and reduces the impact force. Therefore, it is important to control and use the correct dynamic protection.

ATTENTION! The fall factor is also decisive for the magnitude of the impact force - in practice it is not important how long the fall is, but how big the fall factor is. A 5 m long fall with a fall factor of f = 1 will exhibit a significantly lower impact force than a fall of the same length with a fall factor of f = 2. The energy of the climber's fall is absorbed by the so-called "active rope length".

Static extension

The useful static extension is tested by loading the rope with a weight of 80 kg. It should not exceed 10 % for single ropes (one strand of rope) and double ropes (two strands tested simultaneously) and 12 % for half ropes (one strand).

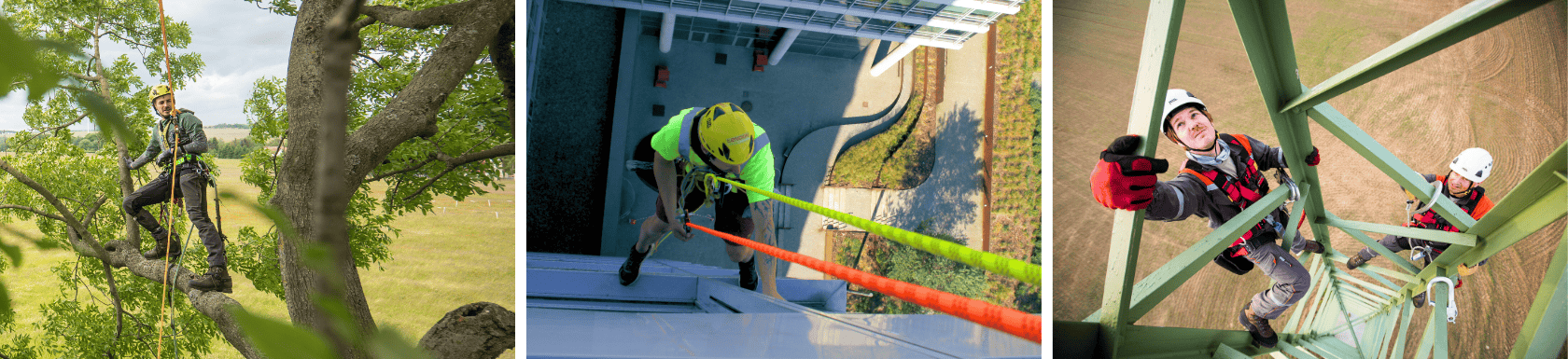

In the test, a special device is used to determine how the braid shifts relative to the core when it is applied to the rope’s surface. The test specimen is stretched to a length of 2,230 mm (+- 10 mm) with this device. EN 892 specifies that the displacement of the braid relative to the core or the core relative to the braid should not exceed 20 mm. If the core shifts relative to the braid when used in practice, bulges and ”stockings” can form. If the ends of the ropes are not sealed properly, the core at the end of the rope may slip out of the braid, or the braid may extend beyond the core. Our ropes have the ends ultrasonically sealed into one integral unit and when the requirements for braid displacement are met, the situation described above does not occur.

Dynamic extension during a first fall

This parameter indicates the rope extension during the first standard fall. The maximum permissible dynamic elongation is 40% at the first fall and takes into account the rope properties better than the static value of the working elongation.

Knotability

One of the important requirements for climbing ropes is excellent flexibility. How to measure it? A single knot is tied on the rope to be tested and single ropes are loaded with a mass of 10 kg. Then the inner diameter of the knot is measured and the knotability coefficient is calculated. This can be a maximum of 1.1 times the rope diameter.

WARNING! Poor rope flexibility makes it practically difficult to tie knots and pass the rope through the carabiners of a progressive locking system. Rope flexibility is reduced by weather and poor care. An in-house testing room, including a drop tower, was built to test TENDON ropes. Therefore, the newly developed ropes that go to European testing laboratories for certification are already fully prepared and have known technical parameters.