PERIOD OF USE

A detailed figure for the ageing of static ropes is only possible as a rough guide and does not exempt the user from the obligation to have the rope inspected by a competent person (person authorized by the manufacturer) after use.

Depending on the frequency and intensity of use, external influences such as abrasion, contamination, mechanical loading (static), rope work (lowering, possibly rappelling), falling loads (dynamic), intense UV exposure, aggressive climates, etc. cause the static and dynamic performance of the static rope (safety margin) to decrease.

The decisive factors for the safety of static ropes in use are the external influencing factors, e.g.:

Sharp edges, which can have fatal consequences even with low rope tension!

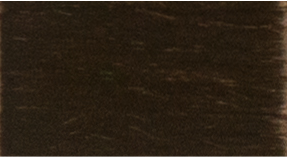

Rappelling and lowering (rope work), which leads to a decrease in dynamic and static performance. For example, during frequent rappelling with heavy loads, the heat due to the friction that necessarily occurs causes the rope braid yarns to stiffen (melt).

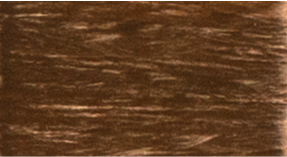

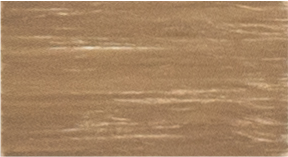

Abrasion causes a gradual weakening of the braid's cohesion. The stronger the abrasion, the more obvious the hairiness of the braid.

Internal abrasion - particles of dirt and rocks entering the inside of the rope, especially in conjunction with high rope performance, lead to the fine fibres in the core and braid of the rope being subject to abrasion. The particles act as abrasive sand and lead to a reduction of the bearing cross-section - especially in the case of frequent rappelling.

Fall load - due to the small dynamic elongation, a fall load greater than or equal to a fall factor of 0.3 must be eliminated. Because, unlike dynamic ropes, the main task of static ropes is not to safely catch falls, but to apply quasi-static loads with only minimal dynamic stresses.

- OCCASIONALLY USED (several times per year) without any intensity of use worth mentioning, without substantial mechanical or fall load, without recognizable abrasion or soiling: 8 - 10 years.

- OCCASIONALLY USED (several times per year) but with high intensity of use, mechanical loading (hanging, lowering and rappelling), no fall load. Signs of use: light abrasion, slight soiling, slight hairiness: 5 - 8 years.

- OFTEN USED (a few times per month) with low intensity of use, no significant mechanical load (hanging, occasional lowering, possibly rappelling), no load from falling, signs of use: no signs of significant abrasion, slight soiling, barely noticeable hairiness: 5 - 8 years.

- VERY OFTEN USED (several times per week) with low intensity use, without substantial mechanical loading or fall load. Signs of use: signs of significant abrasion, slight soiling, recognisable hairiness: 3 - 5 years.

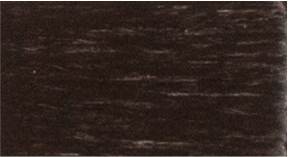

- VERY OFTEN USED (several times per week) with heavy use, mechanical loading (hanging), but no equipment fall. Signs of use: obvious hairiness, signs of abrasion, slight vitrification: 3 - 5 years.

- INTENSIVELY USED (daily) with normal intensity of use, no marked mechanical loading, load from falling. Signs of use: clear hairiness, clear abrasion, heavily soiled: 1-3 years.

- INTENSIVELY USED (daily) with high intensity of use, mechanical loading (hanging), but without fall load. Signs of use: signs of significant abrasion, vitrification, soiling and hairiness:

LOAD DROPS OR OTHER STRONG MECHANICAL, PHYSICAL, CLIMATIC OR CHEMICAL INFLUENCES MAY DAMAGE THE ROPE SO SEVERELY THAT, DEPENDING ON THE CIRCUMSTANCES, IT MAY BE NECESSARY TO TAKE THE ROPE OUT OF SERVICE IMMEDIATELY. THE ROPE MUST BE TAKEN OUT OF USE IMMEDIATELY EVEN IF THE USER HAS THE SLIGHTEST DOUBT ABOUT THE SAFETY AND CONDITION OF THE ROPE.

STORAGE TIME

Ropes designed for caving and canyoning can be stored in an unused condition, as long as they do not have a limitation of use, for up to 5 years.

Optimal storage conditions are a prerequisite, and are:

- a clean place, protected from light;

- no chemical, physical or mechanical influences;

- temperature 15 - 25 °C;

- relative humidity approx. 65 %.

The rope must also be inspected annually by a competent person authorized by the manufacturer.