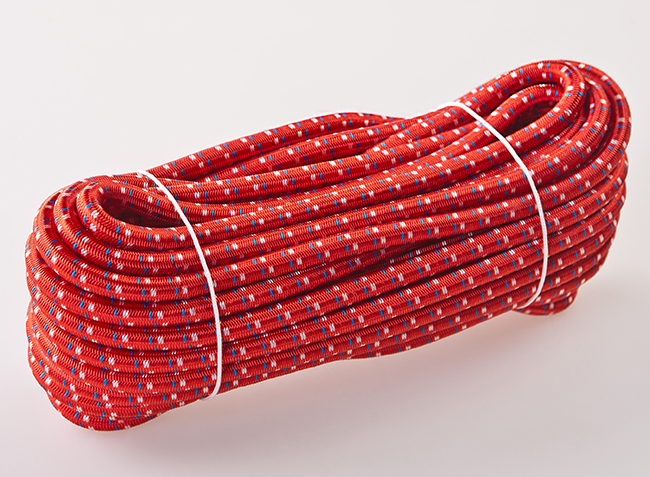

PP-PE monofilament yarn made from a combination of polypropylene and polyethylene and twisted into twine and its name is POLYSTEEL. Used in the manufacture of cords, braided and twisted ropes, boat ropes, netting or cores for steel ropes.

The yarn is resistant to weather, acids, alkalis and solvents, it is non-toxic, colourfast, 100% recyclable and floats on water. It is produced in linear weights of 6,000 - 63,000 denier.